What techniques are used in asbestos management for modern retrofits?

There are a number of benefits to retrofitting an older property. A retrofit can improve the building’s energy efficiency, which can lower energy bills and reduce carbon emissions. Retrofitting can also update obsolete technology and replace old-fashioned design elements. Plus, an upgraded property often means a higher-value property.

However, if the building was constructed prior to the UK asbestos ban in 1999, working with the heating system, flooring, roofing, or a number of other materials can mean disturbing asbestos materials.

Once an asbestos-containing material (ACM) is damaged, disturbed, or deteriorating, it can release toxic fibres into the air. Since the fibres are nearly impossible to detect, they can be unknowingly ingested or swallowed.

Asbestos exposure, especially if it’s prolonged, can lead to major health complications in the future, including various forms of cancer.

In this article, we’ll discuss why asbestos management is a crucial aspect of retrofit projects.

How is an asbestos survey conducted for a retrofit project?

An asbestos survey identifies ACMs on a property, assesses their condition, and determines whether or not additional action is necessary for safety reasons.

What are the types of asbestos surveys?

There are 3 main types of asbestos surveys:

- Management survey: This type of survey helps you monitor and manage asbestos during regular occupation and use of the premises.

- Refurbishment and demolition survey: This type of survey finds and removes asbestos materials prior to planned work.

- Re-inspection survey: This survey should be carried out either annually or when an asbestos material changes, like if it’s deteriorating or has been disturbed.

For a retrofit project, a refurbishment and demolition survey is required.

What is a refurbishment and demolition survey?

According to the Health and Safety Executive, “There is a legal requirement for all ACMs to be removed, as far as reasonably practicable, before major refurbishment or demolition.” The survey will locate, identify and remove ACMs in the work area before the project begins.

Part of this survey involves assessing the building’s structural components, not just the materials that are in the main part of the work area. Some asbestos materials may be hidden, and the asbestos contractor’s job is to safely remove them before the retrofit begins.

What techniques are used for asbestos risk assessment in retrofits?

An asbestos risk assessment determines the risk level of the property’s ACMs and outlines what’s needed for everyone to stay safe. In general, an asbestos risk assessment has five main steps:

- Identify the health risks caused by the asbestos

- Identify who is at risk of asbestos exposure

- Establish safety precautions to limit the risk

- Record details of the risk assessment and inform employees

- Regularly review the assessment to make necessary updates

In some cases, the asbestos risk assessment may conclude that the ACMs on the property aren’t posing a problem and will remain safe as long as they’re not disturbed.

However, in the case of a planned retrofit project, any ACMs in the vicinity are likely to be damaged. Since there are so many construction materials that can include asbestos, the risk level will be high, and the risk assessment must be thorough and detailed.

Here are just some of the details that need to be carefully considered during the risk assessment:

- Types of asbestos present, as some are more dangerous than others

- Friability of the ACMs, meaning how easily they break up and release fibres

- Expected exposure level based on the retrofit project

- Anyone who could be at risk of exposure, including workers, residents and visitors

- Control measures and emergency procedures

The asbestos risk assessment is a necessary part of a retrofit project. It must take place early enough so precautions can be taken before work activities begin.

How are ACMs safely managed during retrofit projects?

Once asbestos materials are found on the work site, they need to be managed so that workers and others on the premises remain safe during the retrofit.

What is asbestos removal?

Asbestos removal is a complex process with various steps, specialty equipment, and distinct safety measures. In general, the process will safely remove ACMs from your home without increasing the risk of asbestos exposure.

Depending on the type of asbestos that’s being removed, licensing may be required. Whether or not a licence is necessary, though, best practices must always be followed to avoid contamination.

Are there alternatives to asbestos removal?

Not all ACMs have to be removed in order to keep people safe. Sometimes, an ACM that’s in good condition and isn’t at risk of being disturbed during the project can stay where it is. In this case, asbestos abatement procedures will be used.

Abatement is used when removal isn’t necessary, possible, or practical. Your asbestos contractor will determine which type of abatement process is best, whether that’s encapsulation, enclosure, repair, or a combination of methods.

What are the best practices for asbestos removal in retrofit projects?

The asbestos removal process is highly controlled, and your contractors should know exactly what to do to keep everyone safe. Best practices for asbestos removal prior to a retrofit include the following:

Timing the asbestos removal

How long asbestos removal or abatement takes depends on the area being worked on, the retrofit projects you’ve planned, the condition of the ACMs, and other factors. Some removal jobs can be completed in as little as a day, while others can take several weeks to finish.

Speaking with an asbestos expert early can help you plan accordingly. You may have to change the timeline of your retrofit in order to safely deal with ACMs beforehand. Considering how dangerous asbestos fibres are, this is a necessary step and should never be skipped.

Choosing an asbestos removal company

With such a high risk of asbestos damage during a retrofit, you want to hire a company or contractor with the proper licensing. Having a regular contractor who’s undergone minimal asbestos training isn’t enough for this type of project.

Our article about choosing an asbestos removal company covers everything you need to consider, including insurance, licensing, cost and more.

Negative pressure and respiratory protective equipment

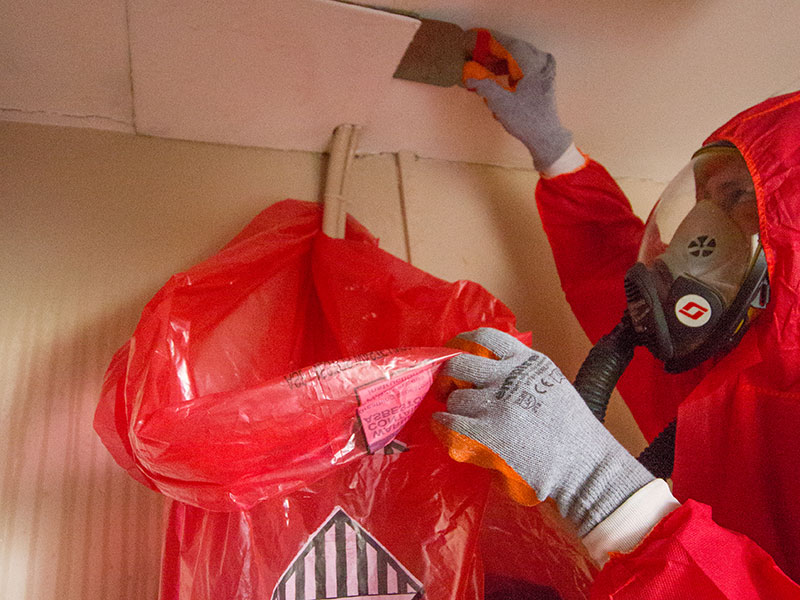

Creating a negative pressure enclosure involves using a HEPA filter around the clock throughout the entire project. This keeps fibres from contaminating areas outside the work enclosure. Workers inside the enclosure will wear special respiratory equipment to ensure they breathe only clean air.

Wet removal techniques

This technique involves wetting the ACMs before removing them. Asbestos materials should remain wet during removal and while they’re bagged for disposal. The wetting method reduces the likelihood of fibres going airborne during removal.

Asbestos waste disposal

In order to protect the environment, proper asbestos waste disposal is as important as removing ACMs safely. Asbestos waste must be double-bagged, clearly labeled, and taken to a disposal site that can handle the specific type of asbestos you’re getting rid of.

What considerations are made for occupied buildings during retrofits?

When asbestos contractors are working in an occupied building, specific precautions must be taken to keep residents, employees, visitors, and anyone else on the premises safe. Those precautions include the following:

- Sealing off the work area so that it can’t be accessed by non-workers and to keep asbestos fibres contained.

- Ensuring that children and pets can’t access the work area. This may mean putting up extra barriers outside the sealed-off work zone.

- Clearly marking the work area as hazardous so people don’t mistakenly go into it.

- Relocating people to other parts of the building to avoid the work area. For example, employees may move to another office temporarily to be farther from the asbestos work.

- When necessary, making it a requirement that the building is not occupied while asbestos removal work takes place.

In addition to the above best practices, all work areas, whether or not the building is occupied, should involve safety measures and equipment for workers so they don’t inhale fibres. That includes air-filtering systems, personal protective equipment, and using removal techniques to limit the release of asbestos fibres.

Final thoughts about asbestos management during retrofits

Building retrofits have positive impacts on the environment, namely lowering emissions and increasing energy efficiency. However, replacing floor, roof, or wall insulation; installing energy-efficient heating systems; and adding solar panels are complex projects that require a lot of pre-planning.

For properties that were built before 2000, you must be vigilant about assessing and mitigating asbestos-related risks. Otherwise, you could put people in harm’s way, as asbestos is a known carcinogen.

If you need help preparing for your retrofit project, contact our asbestos removal experts today.

Written by Brendan Coleman

Brendan Coleman, with decades of experience in the asbestos industry, is a dedicated Quality Manager. Certified as a surveyor and analyst, he is adept in operations and quality management with a keen focus on HSE compliance. His expertise is pivotal in maintaining high safety and efficiency standards. Brendan ensures our UKAS accreditation requirements are consistently met and exceeded, upholding stringent standards in asbestos remediation. His commitment to enhancing quality and customer satisfaction makes him an essential advisor in asbestos management.