What is the asbestos removal process?

Asbestos was once widely used in construction, and though it was banned in 1999, any buildings built prior to 2000 are still likely to contain asbestos. Even one incident of being exposed to asbestos fibres can cause serious diseases later in life, including asbestosis and different types of cancer.

Damaged asbestos releases dangerous fibres that can be inhaled or ingested without realising it. By following a regulated process for identifying and removing asbestos, you’ll keep those on the property safe from serious health complications.

In this article, we’ll answer the question, “Why is proper asbestos removal essential?” and discuss various aspects of the asbestos removal process.

When should asbestos be removed?

Asbestos that’s undamaged and undisturbed doesn’t pose a risk. It’s only when fibres are released that asbestos becomes dangerous to the public. According to the Health and Safety Executive (HSE), “Any badly-damaged asbestos material that is likely to become further damaged should be removed if it cannot be protected.”

Here are a few examples of situations when asbestos-containing materials (ACMs) are their safest:

- The ACM is undamaged, undisturbed, and not wearing down.

- ACMs are in safe areas where they won’t be disturbed by normal activity.

- There isn’t any work planned that could damage the ACMs.

In these cases, the safest option may be to leave the ACM alone. Otherwise, performing removal work could disturb the asbestos and release fibres. That creates a higher risk of exposure than leaving the ACM alone.

Who is qualified to remove asbestos?

Certain types of asbestos work in the UK requires a licence. In general, high-risk asbestos work can only be done by a licensed contractor. Here’s how high-risk asbestos work is legally defined:

- Asbestos exposure is not of low intensity or sporadic

- There’s no assurance that the control limit of exposure to asbestos fibres won’t be exceeded

- The work will involve asbestos coating

- The work is on asbestos insulation or insulating board, and it’s not for a short duration

These aren’t the only circumstances considered high risk. There are other types of asbestos work that may be considered high risk and therefore require a licence.

In order to get an asbestos licence, the proper form must be filled out and submitted. There’s also an asbestos licensing fee that will need to be paid. Next, an HSE inspector will assess the applicant and make a decision about whether or not to grant the licence. In some cases, the applicant will need to take extra steps before they can get an asbestos licence.

What are the steps involved in the asbestos removal process?

There are several steps of the asbestos removal process that must be followed. Every stage of the process is intended to keep people safe, including asbestos workers, employees who work in the building, visitors, and even people passing by outside.

Asbestos survey and identification

The first step of the asbestos removal process is to have an asbestos survey conducted. This will find and identify any asbestos present in the building.

This may be a basic management survey to locate asbestos so the dutyholder is aware of its presence. Or, it may be a more intrusive refurbishment or demolition survey. In that case, the survey will take into account the work that will take place.

In the event of a planned demolition or refurbishment, ACMs that would otherwise stay intact could be damaged. For example, a management survey doesn’t need to consider undisturbed asbestos located in the ceiling or walls. But when more intrusive work will take place, those ACMs could be disturbed.

Risk assessment and removal plan

Next, the asbestos professional or team will perform a detailed risk assessment. This will outline and prepare for risks involved with the specific asbestos removal work needed for the building.

From there, a comprehensive asbestos removal plan can be created. (This may also be called a method statement or work plan.) The plan will outline the scope of work and procedures for containment and decontamination. It will also include the safety measures needed.

Notification

Before asbestos removal work can begin, the appropriate regulatory body, like the HSE, will be notified. This is usually required for any licensed asbestos removal project.

Generally, notification must take place 14 days before work begins. It’s important to plan accordingly to stay legally compliant and to prevent more interruptions than necessary to the normal activity that takes place in the building.

Setup of work area and containment

The asbestos team will now set up a controlled work area. Preventing the spread of airborne asbestos fibres is a big part of creating a safe and contained work area. Often, polythene sheeting, tape, and other materials are used to keep asbestos within the work area, along with airlock systems.

An asbestos enclosure will also have negative pressure so that the air is changed several times an hour, preventing too high a concentration of fibres from building up. Additionally, if the enclosure sheeting accidentally splits, negative pressure measures keep fibres from escaping.

Additionally, personnel will use decontamination units so as not to carry asbestos fibres with them once they leave the work area. There will also be designated exit points for asbestos waste so it doesn’t contaminate anything in the vicinity.

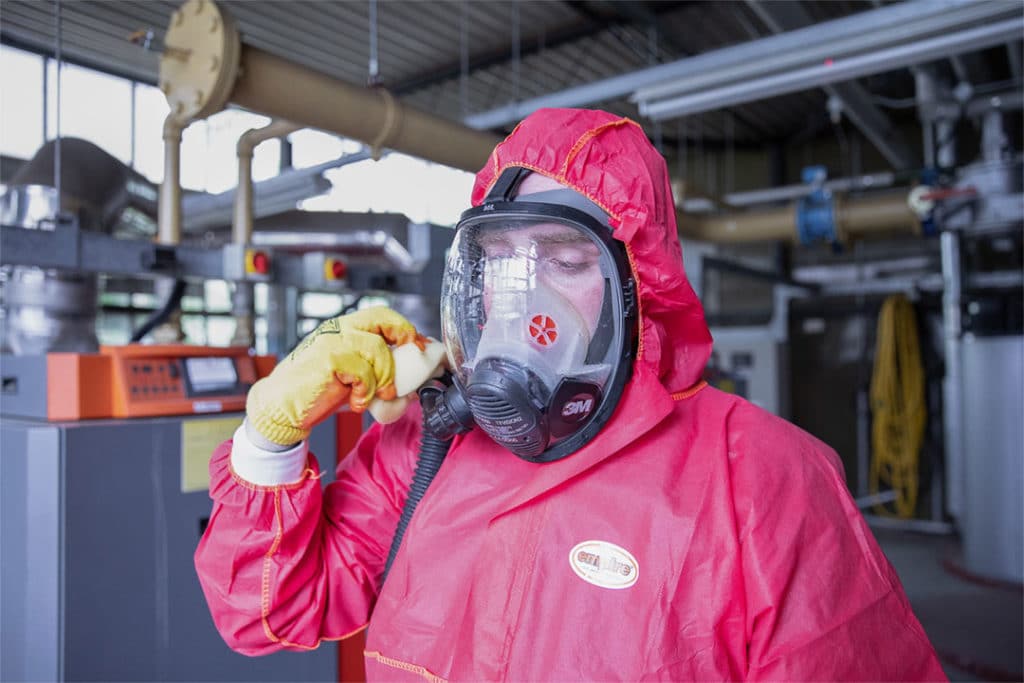

Use of personal protective equipment (PPE)

All workers will wear personal protective equipment (PPE), including adequate respiratory protective equipment (RPE) for the job at hand. PPE includes disposable coveralls and other clothing, along with gloves and laceless boots.

It’s also common for asbestos workers to wear color-coded clothing to communicate which stage of the removal process is taking place. For example, red clothing may be worn in a live enclosure during removal, while blue clothing may be worn when transporting asbestos waste.

Removal of asbestos materials

When removing asbestos materials, the main consideration is preventing or limiting the release of fibres. To do this, the surface of the ACM is wet using a surfactant solution, or it may be sprayed or injected for the same purpose. This minimises how much asbestos dust forms during removal.

In general, any and all ACMs must be removed carefully. They should never be broken into smaller pieces in order to transport them more easily. Breaking up ACMs can release fibres into the air. Not only could this lead to asbestos exposure, but it also results in more to clean up during the decontamination stage.

Decontamination of the work area and equipment

The next step is to decontaminate the work area to ensure that nobody will be exposed to asbestos fibres. Special vacuum cleaners equipped with HEPA filters are used to clean up asbestos dust and debris. Wet-wiping methods are also used to remove residual fibres safely. Additionally, any equipment or tools used during the removal process must also be decontaminated.

An inspector will conduct a visual inspection to determine if the area has been properly cleaned. However, this isn’t the final inspection that will take place — air monitoring and clearance testing will also be conducted as a final step, which we’ll discuss in a minute.

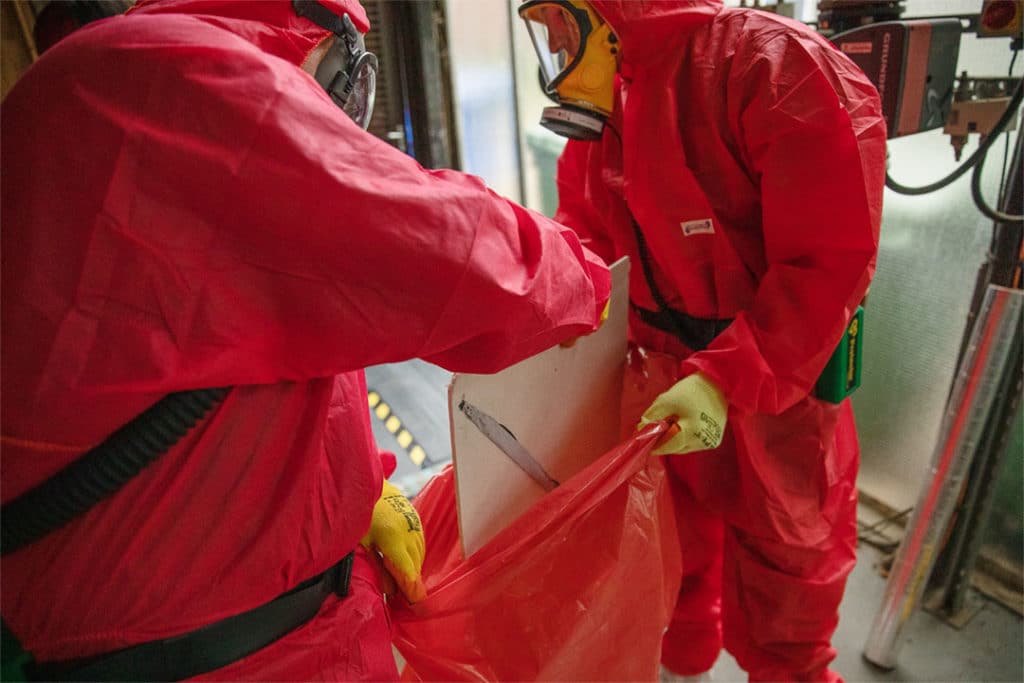

Waste packaging and disposal

It’s important to properly package and dispose of asbestos waste to prevent fibres from releasing. Asbestos should be double-bagged in heavy-duty polythene bags or containers, which should then be sealed and labeled. Asbestos waste can only be disposed of at licensed disposal sites. Additionally, you have to follow local regulations for the transportation and disposal of hazardous waste, including asbestos.

Air monitoring and clearance testing

Even if a work site is cleaned up well and all asbestos waste is removed, you can’t assume that it’s free of asbestos fibres. Since these fibres are undetectable, you won’t be able to see or smell them. Air monitoring has to be conducted to ensure the asbestos fibre concentration in the air falls within the safe amount. (Note that air monitoring also takes place during removal work to keep workers safe.)

Clearance testing should be performed by a licensed asbestos assessor with UKAS accreditation. Monitoring will ensure that the area is safe for reoccupation. Or, it’ll determine that more cleaning and decontamination is necessary before it can be reopened.

Issue of a clearance certificate

When the area passes air testing and is deemed safe for reoccupation, a clearance certificate is issued. This certificate documents that the area has been cleaned and is suitable for re-entry.

Documentation and record-keeping

Any asbestos removal project requires comprehensive records. Everything that occurs should be recorded. That includes all risk assessments, air testing results, disposal receipts, and clearance certificates.

Final thoughts about the importance of following the asbestos removal process

The asbestos removal process ensures that the work area stays safe during and after ACMs have been removed. That’s why every single step is important, from surveying and creating a plan to setting up a safe area, properly removing ACMs, and decontaminating the area afterward. By proactively managing ACMs found on your property, you’ll keep yourself, employees, visitors, and the public safe from the harmful and life-threatening effects of asbestos exposure.

Written by Callum McDonald

Callum McDonald is an expert in asbestos quality management, ensuring rigorous adherence to regulations and high-quality standards in removal projects. His focus on enhancing quality and client satisfaction makes him a crucial asset in safety and compliance within the field. Callum's expertise in technical support and oversight of licensed works underscores his commitment to excellence in asbestos management, providing invaluable guidance to clients in this specialised area.