How do you count asbestos fibres when air testing and monitoring?

Building owners, managers, employers, and asbestos analysts – to cite just a few key stakeholders in the management of asbestos across a wide range of sites – need to be well-versed in the essentials of how they can safely deal with the now-banned mineral. These include the requirements set out under the UK’s stringent asbestos law.

If you are reading this, you might already be aware of many of the basic principles behind asbestos air monitoring and air testing. This service is routinely used to determine the exact concentration of asbestos fibres in the air at a given location (or close to a certain person).

This process, in turn, provides important insight into whether the air in that space is safe, or whether steps will need to be taken to manage the risks. Asbestos, after all, is extremely dangerous. Inhalation or ingestion of the substance heightens the risk of the exposed individual eventually developing a potentially fatal health condition, such as mesothelioma or asbestos-related lung cancer.

As part of the asbestos air testing procedure, it is of critical importance for asbestos fibre counting to be undertaken, and in the correct way. In this article, we have sought to provide an explanation of the methods and procedures for counting asbestos fibres during air testing.

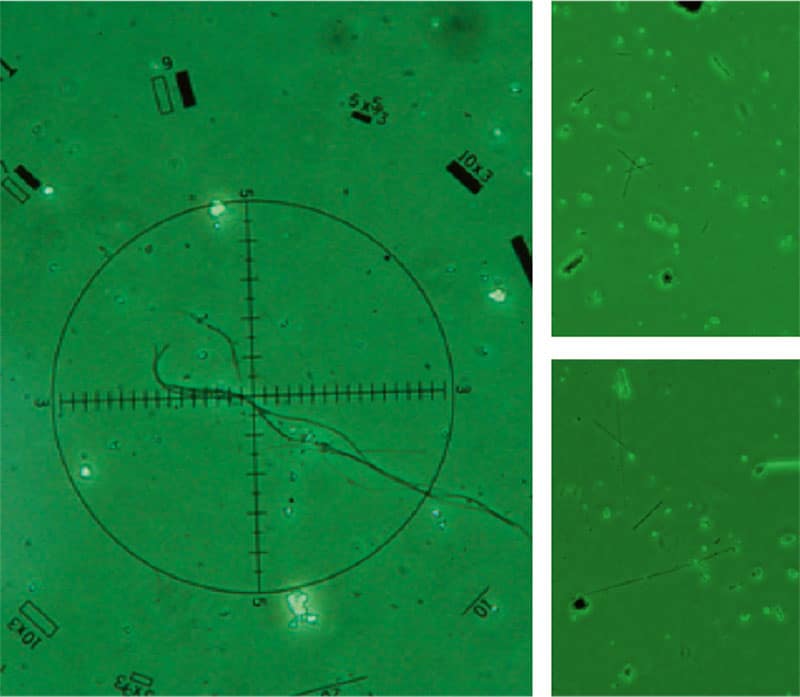

Courtesy of Asbestos Laboratory Services (UK) Ltd

Importance of asbestos fibre counting

The counting of asbestos fibres is important, because it allows for the exact level of risk that asbestos presents in a particular location to be ascertained.

Asbestos air testing and monitoring involves a sample of the air in a specific area – or on a person – being captured by highly trained and certified analysts, using specialised equipment. This sample is then analysed under a microscope, thereby giving the analyst an accurate indication of the level of asbestos fibres in the air at that location.

As we referenced above, exposure to asbestos fibres poses very real health risks; there continue to be around 5,000 deaths from asbestos-related disease every year in the UK.

Furthermore, the UK’s overarching asbestos legislation – the Control of Asbestos Regulations 2012 (CAR 2012) – specifically addresses asbestos air monitoring. Regulation 19 sets out that employers must arrange the regular monitoring of airborne asbestos fibres, and that analysis must be carried out using the 1997 World Health Organization (WHO) recommended method.

Regulation 20 of CAR 2012, meanwhile, sets out standards for air testing and site clearance certification. This regulation stipulates that an employer undertaking its own air testing must do it in a way that complies with the criteria as set out in ISO 17025.

Sampling methods for asbestos air testing

Asbestos air testing and monitoring can be a subject of confusion for many people, as there are so many different terms applied to the types and methods of such testing and analysis.

Here are some areas of distinction that need to be made when it comes to air sampling techniques for asbestos fibre analysis:

Personal vs area sampling

Personal sampling is carried out on an individual person, in order to monitor the personal air the given individual is breathing in.

Area sampling, on the other hand, focuses on a given area of a particular premises (for example, an area where there could be a risk of disturbance being caused to asbestos).

Static vs dynamic sampling

You might have come across the term “asbestos static air testing”; this refers to the process of assessing airborne asbestos fibres in a specific, fixed environment, such as a particular room of a building where asbestos is suspected or known to exist.

This is as opposed to dynamic sampling, or personal sampling, which focuses on the level of asbestos exposure that a particular person is subject to as they dynamically carry out their work and move around a space. Such personal testing typically involves a filter holder being attached to the person’s clothing, and as closely as practicable to their mouth and nose.

Further aspects of the sampling process for asbestos air testing that must be borne in mind include:

The asbestos sampling equipment

We referenced above that specialised equipment is used to capture the air sample for testing. Such equipment encompasses the likes of the air sampling pumps, sampling cassettes, and filters. The mechanical pump is typically used to draw a measured volume of air through a 25mm diameter filter, with the filter subsequently being examined under a microscope.

By engaging the services of well-trained analysts from our team at Oracle Solutions, you can help to ensure such sampling equipment is used in the correct way. This will enable you to be confident that the counting of asbestos fibres in the sample will be done accurately.

Preparation and handling of the air samples

Once the sample of air has been taken, it will need to undergo analysis. Great care will need to be taken to avoid contamination, as well as to preserve the integrity of the sample during its transportation from the origin site to the laboratory (if the analysis is not able to take place on-site).

Laboratory analysis techniques

On arrival in the laboratory, the sample will need to be scrutinised under the microscope. This microscopy process involves the number of respirable fibres being manually counted.

The popular analysis techniques used for the counting of asbestos fibres include:

- Phase contrast microscopy (PCM): the standard method used for the sampling and counting of fibres in the air, with magnification of at least 500x being possible

- Transmission electron microscopy (TEM): a method of identifying asbestos fibres in air samples, including by morphology, crystalline structure, and elemental analysis; magnification of at least 20,000x or higher is typically used

- Scanning electron microscopy (SEM): a method allowing for the accurate and straightforward detection of asbestos, due to magnification of up to 300,000x.

Phase contrast microscopy (PCM)

The basic PCM process can be described as follows: air is drawn at a known flown rate through a filter for a measured time. As a consequence of this process, airborne particles are collected on the filter. Subsequently, the filter is mounted on a glass slide and rendered transparent, so that microscopy examination can take place.

The basic PCM process can be described as follows: air is drawn at a known flown rate through a filter for a measured time. As a consequence of this process, airborne particles are collected on the filter. Subsequently, the filter is mounted on a glass slide and rendered transparent, so that microscopy examination can take place.

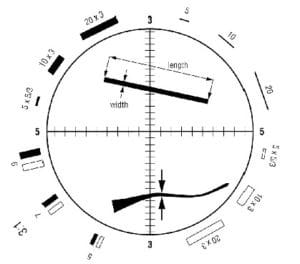

The aforementioned magnification of at least 500x is applied, in order to scrutinise a known fraction of the filtered deposit. At this point, all the fibres visible in a known number of microscope graticule areas can be counted.

The work isn’t done following this, as it will then be necessary to determine the fibre concentration, in terms of fibres per millilitre of air. This is accomplished by dividing the total number of fibres collected on the exposed area of the filter by the volume of sampled air.

The sampling equipment to be used for PCM is subject to certain specific requirements, as described in the Health and Safety Executive (HSE)’s document under the HSG248 series code, Asbestos: The Analysts’ Guide.

One of those requirements – in order to ensure compliance with the WHO standard method – is the use of an open-faced filter holder, fitted with an electrically conducting cylindrical cowl, and exposing a circular area of filter no less than 20mm in diameter.

From the sample preparation and the counting procedure itself, right through to the interpretation of the results including the calculation of the fibre concentration, the PCM process is renowned for its relative speed and cost-effectiveness.

Transmission electron microscopy (TEM)

TEM is one of the two main sampling methods for asbestos air testing, along with PCM. As is the case with phase contrast microscopy, transmission electron microscopy involves ambient air being pumped into filtered air cassettes. Analysis of the collected sample is then carried out using a microscope.

The key difference with TEM, however, is that it uses an electron microscope. This is quite an expensive piece of equipment, but it is capable of scanning and identifying the number of asbestos fibres present.

This brings us onto one of the main disadvantages of PCM – its inability to directly distinguish between asbestos fibres and non-asbestos fibres. This is because PCM relies on fibre morphology – in other words, it is concerned with study of the structure and form of the fibres, rather than chemical composition.

By contrast, TEM can positively and directly identify specific fibres as being asbestos, because it scans for the fibres’ morphology and elemental composition. This helps to make TEM the superior air sampling method when precision and accuracy are among the highest priorities.

There is also no denying, however, the sheer expense of TEM; samples captured using this method can cost five times more than a PCM sample, presuming a standard turnaround time in both cases. Understandably, then, PCM continues to be more widely used than TEM.

Scanning electron microscopy (SEM)

For an especially powerful means of analysing hazardous materials that may contain asbestos, scanning electron microscopy – or SEM – can be an excellent choice.

Like TEM, SEM uses electron microscope equipment, instead of the optical microscope used for PCM. This allows for an especially high level of magnification, of as much as 300,000x, with fibre counting able to take place at 2,000x. The high-resolution imagery that can be produced with this method enables the accurate identification and counting of asbestos fibres.

So, in what circumstances are you likely to turn to SEM over an alternative like PCM? The answer largely lies in the shortcomings of PCM. While phase contrast microscopy is effective in detecting airborne asbestos fibres where it is already known that asbestos has been disturbed in the given location, it isn’t an adequate method in buildings where asbestos fibres may be released at low levels over a prolonged time period.

If you are looking to have asbestos air monitoring carried out in a high-occupancy, frequently used building where such low-level, but long-term asbestos fibre release may be at significant risk of occurring, SEM is likely to be greatly useful. It has a limit of detection of 0.0005 f/cm3, whereas reassurance air testing using PCM commonly has a limit of detection of 0.01 f/cm3.

Quality control and assurance in fibre counting

Quality control is of the utmost importance when it comes to the counting of asbestos fibres from a captured air sample, not least for ensuring the accuracy and reliability of the results.

To this end, proactive and responsible steps need to be taken to ensure the regular calibration and maintenance of the specialised equipment used, such as microscopes.

If you are a building owner, manager, employer, or other dutyholder under CAR 2012 who is comparing options for asbestos air testing, you are also likely to place great emphasis on the credentials of the analysts that you choose.

So, making sure that the analysts you select are certified and undergo ongoing training to keep their knowledge up to date, will likely greatly reassure you about the quality and accuracy of the service that they provide.

Conclusion: accurate asbestos fibre counting is a critical priority

The accuracy of asbestos fibre counting in air testing and monitoring is hugely important. After all, the indication that this process gives of the specific asbestos concentration in a particular location (or being breathed in by a particular person, in the case of personal sampling) will inform the decisions that are taken to manage the risks in the given space.

This is key to the broader efforts that employers, building owners, and other dutyholders need to make in order to adhere to regulatory standards and industry best practices.

If, then, you are reading this as such a stakeholder in the management of asbestos risks at a certain site, we would urge you to ensure that proper asbestos counting procedures are always followed when you arrange for asbestos air testing.

To learn more about our own expertise in asbestos air monitoring, and to receive a free, fast, and transparent quote, please reach out to the Oracle Solutions team today.

Written by Jess Scott

Jess Scott has been an all-round asbestos consultant since 1996. That’s nearly 3 decades of asbestos knowledge. He spends his time sharing that knowledge with the team at Oracle and with their clients. Jess's goal is, and always has been, to use my expertise in helping people to comply with the law. This legal compliance ultimately helps to protect everyone from the harmful effects of asbestos. Jess has acted as an asbestos expert witness in legal cases and is involved in many asbestos educational activities throughout the UK.